|

|

PDF TGS4160 Data sheet ( Hoja de datos )

| Número de pieza | TGS4160 | |

| Descripción | Carbon Dioxide Detection | |

| Fabricantes | Figaro | |

| Logotipo |  |

|

Hay una vista previa y un enlace de descarga de TGS4160 (archivo pdf) en la parte inferior de esta página. Total 11 Páginas | ||

|

No Preview Available !

PRODUCT INFORMATION

TGS 4160 - for the detection of Carbon Dioxide

Features:

* High selectivity to CO2

* Compact size

* Low dependency on humidity

* Long life

Applications:

* Air quality control

* Fermentation process control

The TGS4160 is a hybrid sensor unit composed of a carbon dioxide sensitive

element and a thermistor. The CO2 sensitive element consists of a solid

electrolyte formed between two electrodes, together with a printed heater (Pt)

substrate. By monitoring the change in electromotive force (EMF) generated

between the two electrodes, it is possible to measure CO2 gas concentration.

Adsorbent (zeolite) is filled between the internal cover and the outer cover for

the purpose of reducing the influence of interference gases.

TGS4160 displays good long term stability and shows excellent durability

against the effects of high humidity through the application of innovative

technology in the sensor's electrode design.

The figure below represents typical sensitivity characteristics of

TGS4160. The Y-axis is indicated as ∆EMF which is defined as

follows:

∆EMF=EMF1 - EMF2

where

EMF1=EMF in 350 ppm CO2

EMF2=EMF in listed gas concentration

Sensitivity Characteristics:

80

CO2

CO

EtOH

60

The figure below shows typical humidity dependency for an

energized sensor. Again, the Y-axis is indicated as ∆EMF

which is defined as follows:

∆EMF=EMF1 - EMF2

where

EMF1=EMF in 350 ppm CO2

EMF2=EMF in 1000ppm CO2

Humidity Dependency:

430 70

400 60

370 EMF (350ppm CO2) 50

340 40

40

310 30

20

280 ∆EMF (350ppm CO2 - 1000ppm CO2)

20

250 10

0

100

1000

Gas Concentration (ppm)

10000

220

0

20 40 60 80

Relative Humidity (%)

0

100

IMPORTANT NOTE: OPERATING CONDITIONS IN WHICH FIGARO SENSORS ARE USED WILL VARY WITH EACH CUSTOMER’S SPECIFIC APPLICATIONS. FIGARO STRONGLY

RECOMMENDS CONSULTING OUR TECHNICAL STAFF BEFORE DEPLOYING FIGARO SENSORS IN YOUR APPLICATION AND, IN PARTICULAR, WHEN CUSTOMER’S TARGET GASES

ARE NOT LISTED HEREIN. FIGARO CANNOT ASSUME ANY RESPONSIBILITY FOR ANY USE OF ITS SENSORS IN A PRODUCT OR APPLICATION FOR WHICH SENSOR HAS NOT BEEN

SPECIFICALLY TESTED BY FIGARO.

1 page

TECHNICAL INFORMATION FOR TGS4160

As a result of the electrochemical reaction, electro-

motive force (EMF) would be generated according

to Nernst’s equation:

EMF = Ec - (R x T) / (2F) ln (P(CO2))

where

P(CO2) : Partial pressure of CO2,

Ec : Constant value

R : Gas constant

T : Temperature (K) F : Faraday constant

By monitoring the electromotive force (EMF)

generated between the two electrodes, it is possible

to measure CO2.

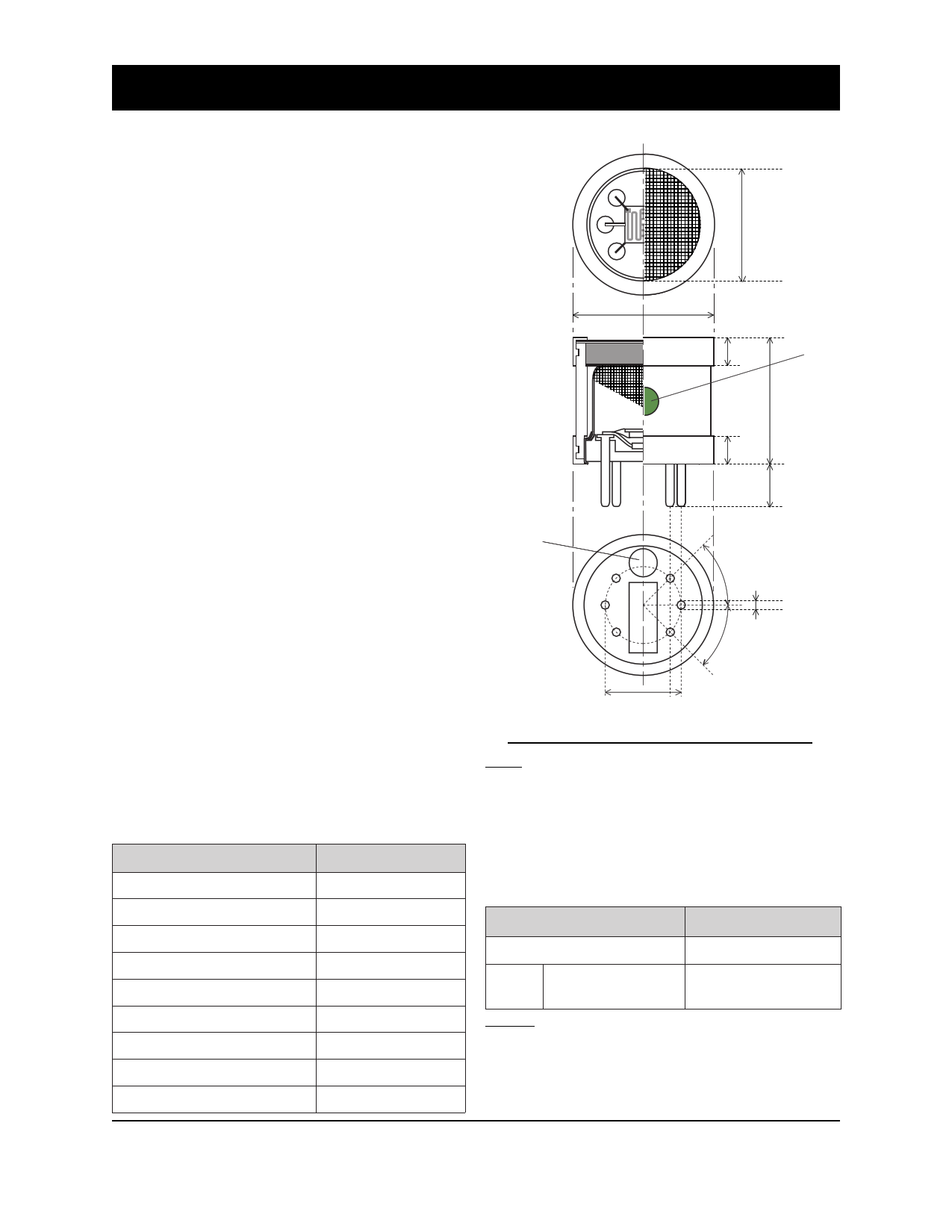

Top view

F I G A RO

ø 17.7±1.0

T G S 4160

ø 24.1±1.0

6.0 ± 0.5

Green Dot

1-5 Basic measuring circuit

Figure 2 shows the basic measuring circuit for

TGS4160. The sensor requires that heater voltage (VH)

be applied to the integrated heater in order to

maintain the sensing element at the optimal temp-

erature for sensing. The sensor’s EMF should be

measured using an operational amplifier with high

impedance (more than 100GΩ) and low bias current

(less than 1 pA) such as Texas Instruments’ model

No. TLC 271. Since the solid electrolyte type sensor

functions as a kind of battery, its absolute EMF value

would drift using this basic circuit. However, the

change of EMF value (∆EMF) maintains a stable

relationship with the changes in CO2 concentration.

Therefore, in order to obtain an accurate measure-

ment of CO2, a special microprocessor for signal

processing should be used with TGS4160. A special

evaluation sensor module which performs the requir-

ed signal processing (AM-4) is available from Figaro.

See Technical Information of AM-4 for further details.

1-6 Circuit &␣ operating conditions

The ratings shown below should be maintained at

all times to insure stable sensor performance:

Item

Specification

Side view

24.3 ±1.0

6.0 ± 0.5

5.8 ± 0.3

White Dot

Bottom view

6

5

4

1

2

3

45˚ ± 1˚30'

ø1.0 ± 0.1

45˚ ± 1˚30'

ø9.5 ± 0.2

Fig. 3 - Sensor dimensions

NOTE: When the sensor is powered, the typical resistance value

of the internal thermistor is around 8.0kΩ due to heat radiated

from the heater. Therefore, the change ratio of thermistor resistance

(RT/RTo) should be used for compensating the temperature

dependency of TGS4160 instead of using the absolute resistance

value of the internal thermistor.

Heater voltage (VH)

Heater resistance (RH) - room temp.

Heater current

Heater power consumption

Resistance of internal thermistor

B constant of internal thermistor

Operating conditions

Storage conditions

Optimal detection concentration

5.0V ± 0.2V DC

11.5 ± 1.1Ω

approx. 250mA

approx. 1.25W

100kΩ ± 5%

3450 ± 2%

-10˚C ~ +50˚C, 5 ~ 95%RH

-20˚C ~ +60˚C, 5 ~ 90%RH

300 ~ 5,000ppm

1-7 Specifications NOTE 1

Item

Specification

EMF in 350ppm of CO2

220 ~ 490mV

∆EMF

EMF (350ppmCO2) -

EMF (3500ppm CO2)

44 ~ 72mV

NOTE 1: Sensitivity characteristics are obtained under the

following standard test conditions:

(Standard test conditions)

Temperature and humidity: 20 ± 2˚C, 65 ± 5% RH

Circuit conditions: VH = 5.0±0.05V DC

Preheating period: 7 days or more under standard circuit conditions

Revised 03/00

3

5 Page

TECHNICAL INFORMATION FOR TGS4160

3-6 Ethanol exposure test

To eliminate the influence of interference gases such

as an ethanol vapor, a zeolite filter is installed in the

cap of TGS4160. To demonstrate the effectiveness of

the zeolite filter, the sensor was exposed in 3% of

ethanol gas for a period of 600 days. During this test,

∆EMF values of ethanol were measured. ∆EMF is

defined as follows:

∆EMF=EMF1 - EMF2

where

EMF1=EMF in 350ppm CO2

EMF2=EMF in 350 ppm CO2 and 300ppm EtOH

The results of the above test are shown in Figure 16.

As the stable ∆EMF values show, the zeolite filter

has sufficient ability to eliminate the influence of

interference gases over an extended period of time.

40

20

0

-20

-40

0 100 200 300 400 500 600 700

Time (days)

Fig. 16 -Effect of ethanol exposure

3-7 Effect of exposure to high CO2 concentration

Figure 17 shows the sensor characteristics of TGS4160

in high concentrations of CO2. This data suggests that

TGS4160 can detect CO2 in excess of 100000ppm.

However, it should be noted that the ∆EMF values

would likely devitae from their initial values after

exposure to high concentrations of CO2. This would

occur due to a shift in the chemical equilibrium

between the sensing electrode and CO2 gas.

4. Notes

The following cautions regarding storage and

installation of TGS4160 should be observed to

prevent permanent damage to the sensor:

1) Install/store indoors, avoiding dew condensation,

silicone vapor, and exposure to alkaline metals (Na,

Li, etc.).

2) Avoid places where vibration or mechanical shock

may occur.

3) The sensor should not be stored in high humidity

or temperature conditions. Sensors should be stored

in an aluminum-coated sealing bag together with

desiccant.

4) The sensor should be mounted on circuit board

using manual soldering.

400

350

300

250

200

150

100

1000

10000

CO2 concentration (ppm)

100000

Fig. 17 - Effect of exposure to high CO2 concentrations

Revised 03/00

9

11 Page | ||

| Páginas | Total 11 Páginas | |

| PDF Descargar | [ Datasheet TGS4160.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| TGS4160 | Carbon Dioxide Detection | Figaro |

| TGS4161 | CO2 Sensor | Figaro |

| TGS4161 | Technical Information for Carbon Dioxide Sensors | Figaro |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |