|

|

PDF A3150 Data sheet ( Hoja de datos )

| Número de pieza | A3150 | |

| Descripción | PROGRAMMABLE/ CHOPPERSTABILIZED/ HALL-EFFECT SWITCH | |

| Fabricantes | Allegro MicroSystems | |

| Logotipo |  |

|

Hay una vista previa y un enlace de descarga de A3150 (archivo pdf) en la parte inferior de esta página. Total 12 Páginas | ||

|

No Preview Available !

3150

PROGRAMMABLE, CHOPPER-

STABILIZED, HALL-EFFECT SWITCH

The A3150JLT and A3150JUA programmable switches provide

tooth/valley recognition in large gear-tooth sensing applications. Each

sensor consists of a single element, chopper-stabilized Hall-effect IC

that can be programmed to the desired magnetic switch point, opti-

mizing sensor airgap and timing accuracy performance after final

PTCT

packaging. The small package can be easily assembled and used in

V

TCC

UC .1 2

3

PRODE ONsLiYgnDwg.PH-003-2

ED NC dePRELIMINARY INFORMATION

U E(subject to change without notice)

IN R wApril 12, 1999

NT FE r neABSOLUTE MAXIMUM RATINGS

CO RE foat TA = 25°C

Supply Voltage, VCC ........................... 26.5 V

0Reverse Supply Voltage, VRCC ............ -30 V

IS R 5Overvoltage Supply Current, ICC ..... 100 mA

D O 2Magnetic Flux Density, B ............ Unlimited

F 3Output Current, IOUT ..... Internally Limited

Output OFF Voltage, VOUT ................. 26.5 V

AReverse Output Current, IROUT ......... -50 mA

— eOperating Temperature Range,

TA ............................... -40°C to +115°C

UsStorage Temperature, TS ................... +170°C

conjunction with a wide variety of gear/target shapes and sizes. The

two devices differ only in package style.

The sensing technology used for this sensor is Hall-effect based.

The sensor incorporates a single-element Hall IC that switches in

response to magnetic signals created by a ferrous target. The program-

mability of the circuit eliminates magnet and system offsets such as

those caused by tilt yet provides zero-speed detection capabilities

without the associated running jitter inherent in classical digital solu-

tions.

A proprietary dynamic offset cancelation technique, with an

internal high-frequency clock, reduces the residual offset voltage,

which is normally caused by device overmolding, temperature

dependancies, and thermal stress. This technique produces devices that

have an extremely stable quiescent output voltage, are immune to

mechanical stress, and have precise recoverability after temperature

cycling. Many problems normally associated with low-level analog

signals are minimized by having the Hall element and amplifier in a

single chip. Output precision is obtained by internal gain adjustments

during the manufacturing process and operate-point programming in the

user’s application.

This sensor system is ideal for use in gathering speed, position, and

timing information using gear-tooth-based configurations. The

A3150JLT/JUA are particularly suited to those applications that require

accurate duty cycle control or accurate edge detection. The lower

vibration sensitivity also makes these devices extremely useful for

transmission speed sensing.

Continued next page

Always order by complete part number: the prefix 'A' + the basic four-digit

part number + a suffix to indicate operating temperature range +

a suffix to indicate package style, e.g., A3150JLT .

1 page

3150

PROGRAMMABLE, CHOPPER-

STABILIZED, PRECISION,

HALL-EFFECT SWITCH

FUNCTIONAL DESCRIPTION

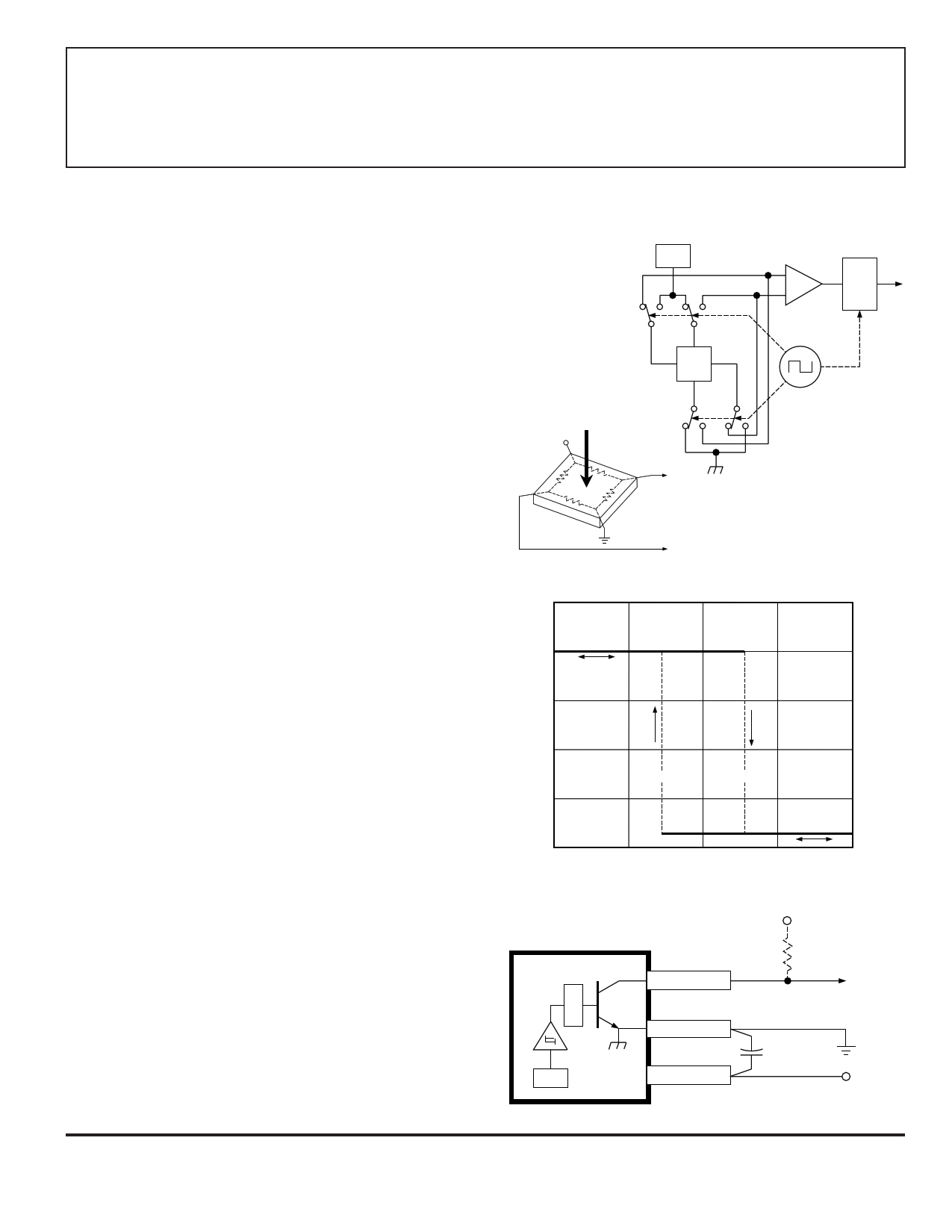

Chopper-Stabilized Technique. These devices use a

proprietary dynamic offset cancellation technique, with an

internal high-frequency clock to reduce the residual offset

voltage of the Hall element that is normally caused by device

overmolding, temperature dependencies, and thermal stress.

This technique produces devices that have an extremely stable

quiescent Hall output voltage, are immune to thermal stress, and

have precise recoverability after temperature cycling. This

technique will also slightly degrade the device output repeatabil-

ity.

The Hall element can be considered as a resistor array

similar to a Wheatstone bridge. A large portion of the offset is a

result of the mismatching of these resistors. The chopper-

stabilizing technique cancels the mismatching of the resistors by

changing the direction of the current flowing through the Hall

plate and Hall voltage measurement taps, while maintaining the

Hall-voltage signal that is induced by the external magnetic flux.

The signal is, then, captured by a sample-and-hold circuit.

Operation. The output of these devices switches low (turns

ON) when a magnetic field (south pole) perpendicular to the

Hall sensor exceeds the operate point threshold (BOP). After

turn-ON, the output is capable of sinking 25 mA and the output

voltage is VOUT(SAT). When the magnetic field is reduced below

the release point (BRP), the device output goes high (turns OFF).

The difference in the magnetic operate and release points is the

hysteresis (Bhys) of the device. This built-in hysteresis allows

clean switching of the output even in the presence of external

mechanical vibration and electrical noise.

Applications. It is strongly recommended that an external

bypass capacitor be connected (in close proximity to the Hall

sensor) between the supply and ground of the device to reduce

both external noise and noise generated by the chopper-stabiliza-

tion technique.

B

+V

+V

VCC

0

0

The simplest form of magnet that will operate these devices

is a bar magnet with the south-seeking pole towards the branded

surface of the device. Many other methods of operation are

possible. Extensive applications information on magnets and

Hall-effect sensors is also available in the Allegro Electronic

Data Book AMS-702 or Application Note 27701, or

www.allegromicro.com

REG

X

—

HALL

VOLTAGE

+

Dwg. AH-011-2

Dwg. EH-012

B RP

B OP

FLUX DENSITY

VOUT(SAT)

+B

Dwg. GH-007-2

SUPPLY

OUTPUT

0.1 µF

SUPPLY

Dwg. EH-013

www.allegromicro.com

5 Page

3150

PROGRAMMABLE, CHOPPER-

STABILIZED, PRECISION,

HALL-EFFECT SWITCH

PACKAGE DESIGNATOR 'UA'

Dimensions in Inches

(controlling dimensions)

0.164

0.159

0.062

45° 0.058

Dimensions in Millimeters

(for reference only)

4.17

4.04

1.57

45° 1.47

0.122

0.117

0.085 1 2 3 0.031

MAX

0.640

0.600

SEE NOTE

0.0189

0.0142

45°

0.0173

0.0138

3.10

2.97

2.16 1 2 3 0.79

MAX

16.26

15.24

SEE NOTE

0.48

0.36

45°

0.44

0.35

0.050

BSC

Dwg. MH-014E in

1.27

BSC

Surface-Mount Lead Form (Suffix '-TL')

0.095

±0.005

2.41

±0.13

Dwg. MH-014E mm

0.002

MAX

0.051

MAX

0.004 0°–8°

MAX

0.020

MIN

FLAT

Dwg. MH-015 in

0.10 0°–8°

MAX

0.51

MIN

FLAT

Dwg. MH-015 mm

NOTES: 1. Tolerances on package height and width represent allowable mold offsets. Dimensions given are measured at the widest point (parting line).

2. Exact body and lead configuration at vendor’s option within limits shown.

3. Height does not include mold gate flash.

4. Recommended minimum PWB hole diameter to clear transition area is 0.035” (0.89 mm).

5. Where no tolerance is specified, dimension is nominal.

www.allegromicro.com

11 Page | ||

| Páginas | Total 12 Páginas | |

| PDF Descargar | [ Datasheet A3150.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| A3150 | PROGRAMMABLE/ CHOPPERSTABILIZED/ HALL-EFFECT SWITCH | Allegro MicroSystems |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |