|

|

PDF LFH1036 Data sheet ( Hoja de datos )

| Número de pieza | LFH1036 | |

| Descripción | SMD | |

| Fabricantes | LUXPIA | |

| Logotipo |  |

|

Hay una vista previa y un enlace de descarga de LFH1036 (archivo pdf) en la parte inferior de esta página. Total 16 Páginas | ||

|

No Preview Available !

Specification for Approval

( Version 1.0 )

Part No. : LFH1036

comments

LUXPIA Co., Ltd.

Designed by Checked by Approved by

Approved by Approved by Approved by

///

www.DataSheet4U.com

Date : . . .

///

Date : . . .

LUXPIA CO.,LTD.

948-1, Dunsan-Li Bongdong-Eup, Wanju-Gun, JeonBuk, Korea Tel 82-63-260-4500 Fax 82-63-261-8255

1 page

5. Materials

item

LED chip

wire

lead frame

encapsulation

heat-resistant polymer

material

InGaN, AlInGap

gold

copper alloy/Ni/Ag plating

Silicone resin

PPA

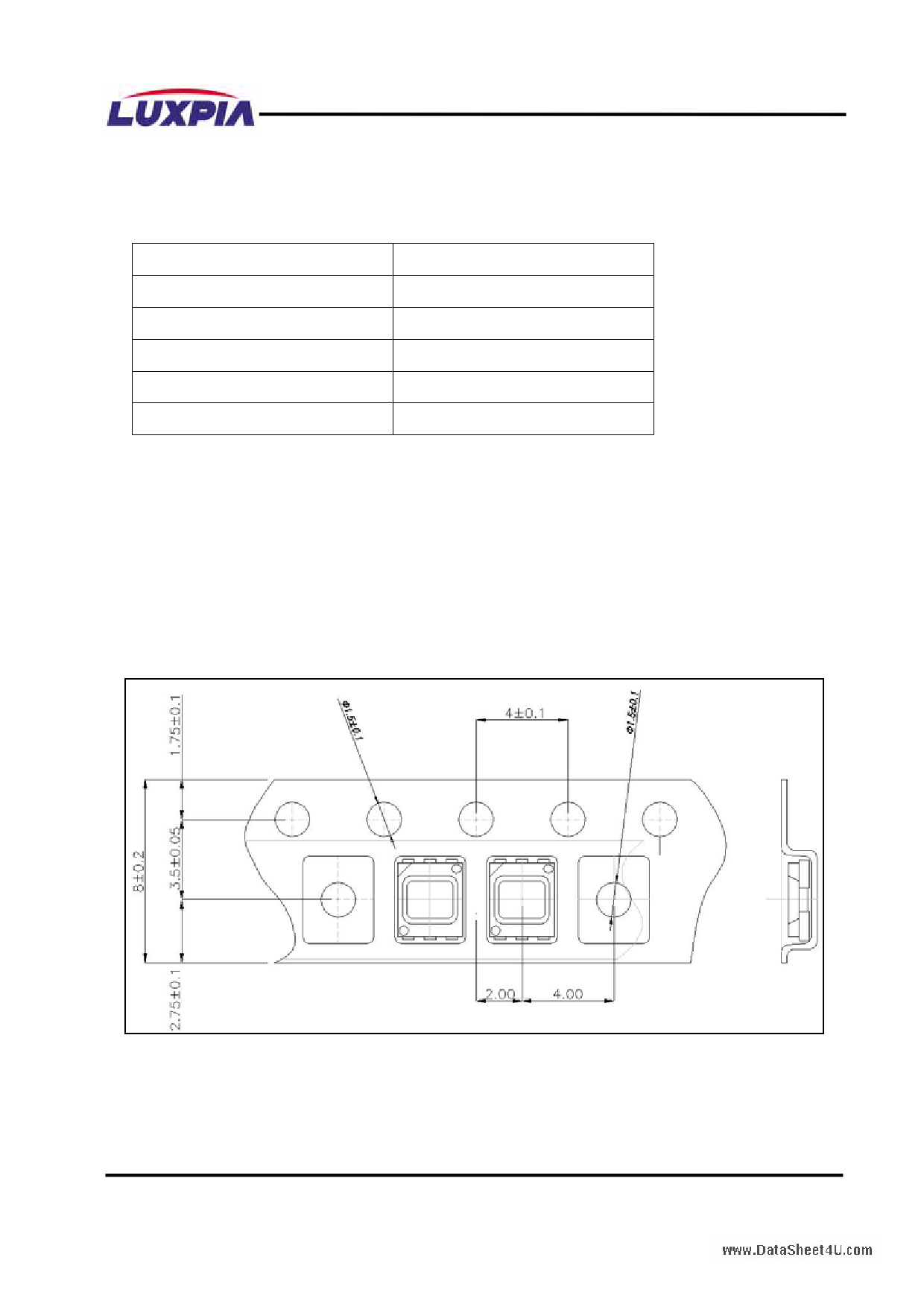

6. Taping

6.1. tape (material : PS conductive, 104~105Ω)

(Units : mm)

www.DataSheet4U.com

4/15

5 Page

• Occasionally there is a brightness decrease caused by the influence of heat or ambient

atmosphere during air reflow. It is recommended that the User use the nitrogen reflow method.

• Repairing should not be done after the LEDs have been soldered. When repairing is unavoidable,

a double-head soldering iron should be used. It should be confirmed beforehand whether the

characteristics of the LEDs will or will not be damaged by repairing.

• Reflow soldering should not be done more than two times.

• When soldering, do not put stress on the LEDs during heating.

• After soldering, do not warp the circuit board.

(5) Cleaning

• It is recommended that isopropyl alcohol be used as a solvent for cleaning the LEDs. When

using other solvents, it should be confirmed beforehand whether the solvents will dissolve the

package and the resin or not. Freon solvents should not be used to clean the LEDs because of

worldwide regulations. Do not clean the LEDs by the ultrasonic. When it is absolutely necessary,

the influence of ultrasonic cleaning on the LEDs

depends on factors such as ultrasonic power and the assembled condition. Before cleaning, a pre-

test should be done to confirm whether any damage to the LEDs will occur.

(6) Static Electricity

• Static electricity or surge voltage damages the LEDs. It is recommended that a wrist band or an

anti-electrostatic glove be used when handling the LEDs.

• All devices, equipment and machinery must be properly grounded. It is recommended that

measurements be taken against surge voltage to the equipment that mounts the LEDs.

• When inspecting the final products in which LEDs were assembled,it is recommended to check

whether the assembled LEDs are damaged by static electricity or not. It is easy to find static-

damaged LEDs by a light-on test or a VF test at a lower current (below 1mA is recommended).

• Damaged LEDs will show some unusual characteristics such as the leak current remarkably

increases, the forward voltage becomes lower, or the LEDs do not light at the low current.

- criteria : VF > 2.0V at IF=0.5

(7) Others

• Care must be taken to ensure that the reverse voltage will not exceed the absolute maximum

rating when using the LEDs with matrix drive.

• The LED light output is strong enough to injure human eyes. Precautions must be taken to

prevent looking directly at the LEDs with unaided eyes for more than a few seconds.

• Flashing lights have been known to cause discomfort in people; you can prevent this by taking

precautions during use. Also, people should be cautious when using equipment that has had LEDs

incorporated into it.

10. Warranty

(1) Luxpia warrants that its LEDs conform to the foregoing specifications and that Luxpia will

convey good title to all LEDs sold.

(2) LUXPIA disclaims all other warranties including the implied warranties of merchantability and

fitness for a particular purpose.

(3) In the event any LED supplied by Luxpia is found not to conform to the foregoing specifications

www.DatwtahSiathhteietnth4enUi.nUcoesmteyr

days of receipt, Luxpia will repair or replace the LED, at Luxpia’s discretion,

(a) promptly notifies Luxpia in writing of the details of the defect (b) ships

provided

the LEDs

at the User’s expense to Luxpia for examination, and (c) the defect is due to the negligence of

Luxpia and not mishandling or misuse by the User.

10/15

11 Page | ||

| Páginas | Total 16 Páginas | |

| PDF Descargar | [ Datasheet LFH1036.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| LFH1033 | SMD | LUXPIA |

| LFH1036 | SMD | LUXPIA |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |