|

|

PDF ECEVG Data sheet ( Hoja de datos )

| Número de pieza | ECEVG | |

| Descripción | Aluminum Electrolytic Capacitor/V-G | |

| Fabricantes | Panasonic Semiconductor | |

| Logotipo | ||

Hay una vista previa y un enlace de descarga de ECEVG (archivo pdf) en la parte inferior de esta página. Total 9 Páginas | ||

|

No Preview Available !

Aluminum Electrolytic Capacitor/V-G

Surface Mount Type

Series: G Type : V

Discontinued

s Features Endurance :105°C 1000 h

sSpecification

Operating temp. range

Rated W.V. range

Nominal cap. range

Capacitance tol.

DC leakage current

-40 to + 105°C

6.3 to 50 V .DC

0.1 to 470 µ F

±20 % (120Hz/+20°C)

I < 0.01 CV or 3 (µ A) after 2 minutes (Whichever is the greater)

tan δ

(120Hz / +20°C)

W.V. 6.3 10 16 25 35 50

tan δ 0.30 0.22 0.16 0.14 0.12 0.12

Characteristics

at Low Temperature

Endurance

Shelf life

Resistance to

Soldering Heat

W.V. (V) 6.3 10 16 25 35 50

-25 / +20 °C 4 3 2 2 2 2 ( Impedance ratio at 120 Hz)

-40 / +20 °C 8 6 4 4 3 3

After applying rated working voltage for 1000 hours at +105 ± 2°C, and then being atabilized at

+20°C, capacitors shall meet following limits.

Capacitance change < ±20% of initial measured value

tan δ

< 200% of initial specified value

DC leakage current < initial specified value

After storage for 1000 hours at +105 ±2°C with no voltage applied and then being stabilized

at +20°C, capacitor shall meet the limits specified in “Endurance”.

After reflow soldering (230°C of peak temperature and reflow time less than 20 seconds.) and

then being stabilized at 20°C, capacitor shall meet the following limits, (Infrared ray oven is also

available.)

Capacitance change < ±10% of initial measured value

tan δ

< initial specified value

DC leakage current < initial specified value

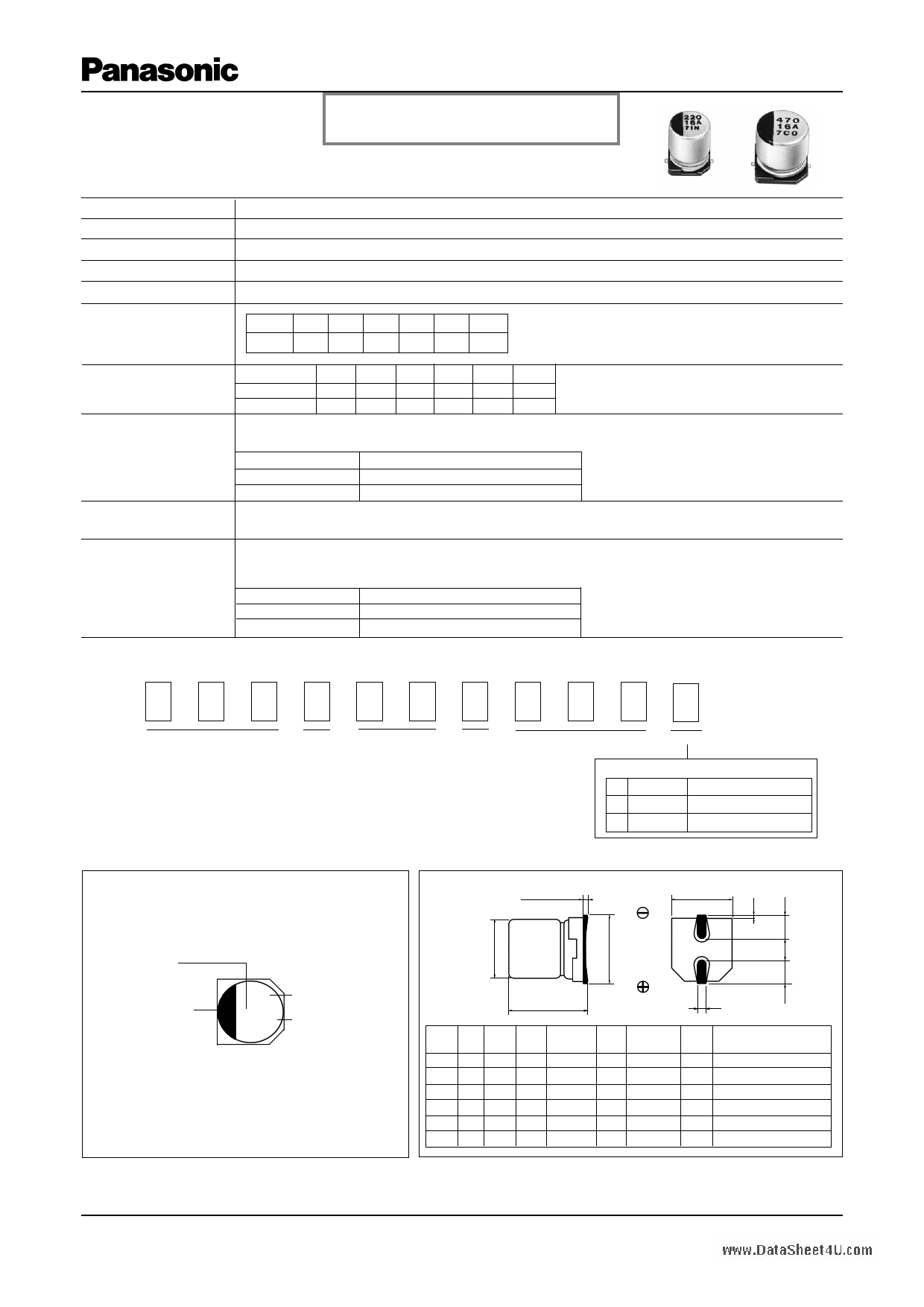

sExplanation of Part Number

ECE

Common code

V

Shape

s Marking

G

W.V. code Series code Capacitance code

Suffix

Taping

R W=12 mm φ4(B)

P W=16 mm φ5,φ6.3,φ8x6.2(C,D,E)

P W=24 mm φ8x10.2, φ10x10.2(F,G)

s Dimensions in mm (not to scale)

Example : 50V22µF

0.3 max

@A±0.2 ( ) reference size

Rated voltage (V.DC)

(-): Negative polarity

marking

www.DataSheet4U.com

22

50 G

Capacitance (µF)

Series identification

E,F,G= L±0.3

L+-00..21

w

(mm)

Size

code

D

L

A

H

I

B 4.0 5.4 4.3 5.5 MAX 1.8

C 5.0 5.4 5.3 6.5MAX 2.2

D 6.3 5.4 6.6 7.8MAX 2.6

E 8.0 6.2 8.3 9.5MAX 3.4

F 8.0 10.2 8.3 10.0MAX 3.4

G 10.0 10.2 10.3 12.0MAX 3.5

WP

0.65 ±0.1 1.0

0.65±0.1 1.5

0.65± 0.1 1.8

0.65±0.1 2.2

0.90±0.2 3.1

0.90±0.2 4.6

K

0.35 -0.20 to +0.15

0.35 -0.20 to +0.15

0.35 -0.20 to +0.15

0.35 -0.20 to +0.15

0.70 ±0.2

0.70 ±0.2

Design, Specifications are subject to change without notice. Ask factory for technical specifications before purchase and/or use.

Whenever a doubt about safety arises from this product, please inform us immediately for technical consulation without fail.

Mar. 2005

Ñ EE3 Ñ

1 page

Aluminum Electrolytic Capacitor

1.3 Common Application Conditions to Avoid

The following misapplication load conditions will

cause rapid deterioration to capacitor electrical

parameters. ln addition, rapid heating and gas

generation within the capacitor can occur causing

the pressure relief vent to operate and resuItant

leakage of electrolyte. Under extreme conditions,

explosion and fire could result. Leakinq electrolyte

is combustible and electrically conductive.

(1) Reverse Voltaqe

DC capacitors have polarity. Verify correct polarity

before inser tion. For circuits with changing or

uncertain polarity,use DC bipolar capacitors. DC

bipolar capacitors are not suitable for use in AC

circuits.

(2) Charqe/Discharqe Applications

Standard capacitors are not suitable for use in

repeating charge/discharge applications. For

charqe/discharqe applications consult us and advise

actual conditions.

(3) Overvoltage

Do not appIy voltaqes exceeding the maximum

specified rated voltages. Voltage up to the surge

voltage rating are acceptable for short periods of

time. Ensure that the sum of the DC voltage and

the superimposed AC ripple voltage does not

exceed the rated voltage.

(4) Ripple Current

Do not apply ripple currents exceeding the maximum

specified value. For high ripple current applications,

use a capacitor designed for high rippIe currents

or contact us with your requirements.

Ensure that allowable ripple currents superimposed

on low DC bias voltages do not cause reverse voltage

conditions.

1.4 Using Two or More Capacitors in Series

or Parallel

(1) Capacitors Connected in Parallel

The circuit resistance can closely approximate the

series resistance of the capacitor causing an

imbalance of ripple current loads within the

capacitors. Careful design of wiring methods can

minimize the possibility of excessive ripple currents

applied to a capacitor.

(2) Capacitors Connected in Series

Normal DC leakage current differences among

capacitors can cause voltage imbalances. The use

of voltage divider shunt resistors with consideration

to leakage currents, can prevent capacitor voltage

imbaIances.

1.5 Capacitor Mounting Considerations

www.(D1a)taDSoheuebt4IeU.-coSmided Circuit Boards

Avoid wiring Pattern runs which pass between

the mounted capacitor and the circuit board. When

dipping into a solder bath, excess solder may collect

under the capacitor by capillary action and

shortcircuit the anode and cathode terminals.

(2) Circuit Board Hole Positioning

The vinyl sleeve of the capacitor can be damaged

if solder passes through a lead hole for

subsequently processed parts. Special care when

locating hole positions in proximity to capacitors is

recommended.

(3) Circuit Board Hole Spacing

The circuit board holes spacing should match the

capacitor lead wire spacing within the specified

tolerances. Incorrect spacing can cause excessive

lead wire stress during the insertion process. This

may resuIt in premature capacitor failure due to

short or open circuit, increased leakage current,

or electrolyte leakage.

(4)Land/Pad Pattern

The circuit board land/pad pattern size for chip

capacitors is specified in the following table.

[ Table of Board Land Size vs. Capacitor Size ]

c

b a b Board land part

(mm)

Size a b c

A(φ3)

0.6 2.2 1.5

B(φ4)

1.0 2.5. 1.6

C(φ5)

1.5 2.8 1.6

D(φ6.3)

1.8 3.2 1.6

E(φ8 x 6.2L)

2.2 4.0 1.6

F(φ8 x 10.2L)

3.1 4.0 2.0

G(φ10 x 10.2L) 4.6 4.1 2.0

Among others, when the size a is wide , back fillet can

not be made, decreasing fitting strength.

h Decide considering mounting condition, solderability

and fitting strength, etc. based on the design

standards of your company.

Design, Specifications are subject to change without notice. Ask factory for technical specifications before purchase and/or use.

Whenever a doubt about safety arises from this product, please inform us immediately for technical consulation without fail.

Mar. 2005

– EE18 –

5 Page | ||

| Páginas | Total 9 Páginas | |

| PDF Descargar | [ Datasheet ECEVG.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| ECEV1xxxx | Aluminium Electrolytic Capacitors | Panasonic |

| ECEVG | Aluminum Electrolytic Capacitor/V-G | Panasonic Semiconductor |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |