|

|

PDF ELJ-750-629 Data sheet ( Hoja de datos )

| Número de pieza | ELJ-750-629 | |

| Descripción | Jumbo-LED | |

| Fabricantes | EPIGAP | |

| Logotipo |  |

|

Hay una vista previa y un enlace de descarga de ELJ-750-629 (archivo pdf) en la parte inferior de esta página. Total 5 Páginas | ||

|

No Preview Available !

Jumbo-LED

Radiation

Infrared

5,08

12

Type

4W

ELJ-750-629

20.11.2007

rev. 01

Technology

AlGaAs/AlGaAs

Case

Plastic lens, metal case

Description

High-power infrared LED in an aluminium case, with

thread socket for easy handling and heat sink

mounting

12

M10

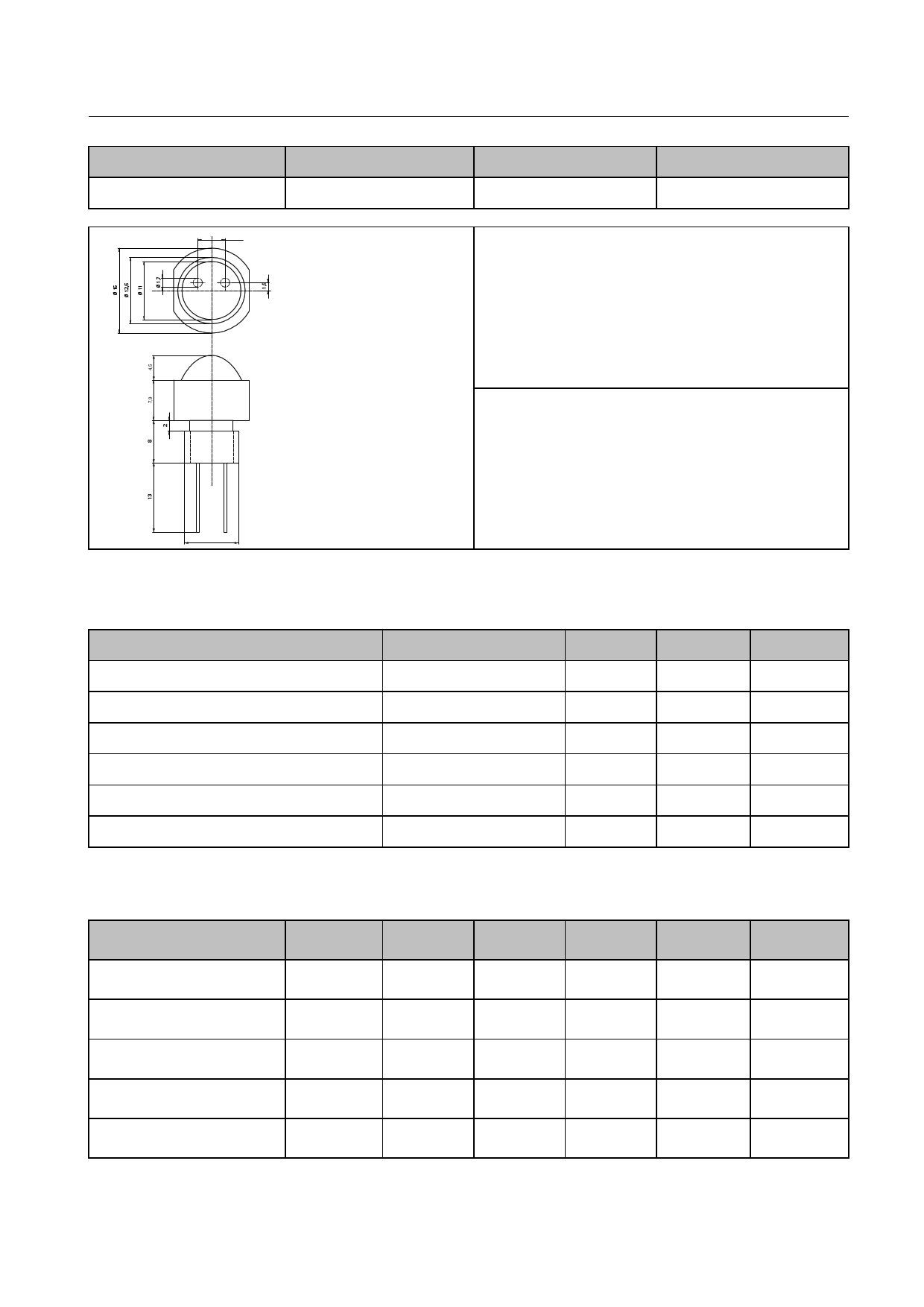

Outline:

H = 12.4 mm (± 0.5)

D = 16 mm (± 0.5)

Thread M10

Pin 1 – cathode

Pin 2 – anode

Applications

Medical appliances, remote control and optical

communications, light barriers, measurement systems

Absolute Maximum Ratings

at Tamb = 25°C, on heat sink (S ≥ 200 cm²), unless otherwise specified

Parameter

Test сonditions

DC forward current

on heat sink

Peak forward current

Power dissipation

tp≤10 µs, f≤500 Hz

on heat sink

Operating temperature range

on heat sink

Storage temperature range

on heat sink

Junction temperature

on heat sink

Symbol

IF

IFM

P

Tamb

Tstg

Tj

Value

1.2

2.0

4

-25 to +100

-25 to +100

100

Unit

A

A

W

°C

°C

°C

Electrical Characteristics

Tamb = 25°C, unless otherwise specified

Parameter

Test

conditions

Symbol

Min

Typ Max

Unit

Forward voltage

IF = 350 mA

VF

1.9 2.5

V

Forward voltage*

IF = 1000 mA

VF

2.5 3

V

Switching time

IF = 350 mA

tr, tf

60

ns

Reverse voltage

IR = 10 µA

Thermal resistance

junction-case

*only recommended on optimal heat sink

VR

RthJC

5

10

K/W

We reserve the right to make changes to improve technical design and may do so without further notice.

Parameters can vary in different applications.All operating parameters must be validated for each customer application by the customer.

EPIGAP Optoelektronik GmbH, D-12555 Berlin, Köpenicker Str.325 b, Haus 201

Tel.: +49-30-6576 2543, Fax : +49-30-6576 2545

1 of 5

www.DataSheet.in

1 page

Jumbo-LED

Handling precautions

ELJ-750-629

20.11.2007

rev. 01

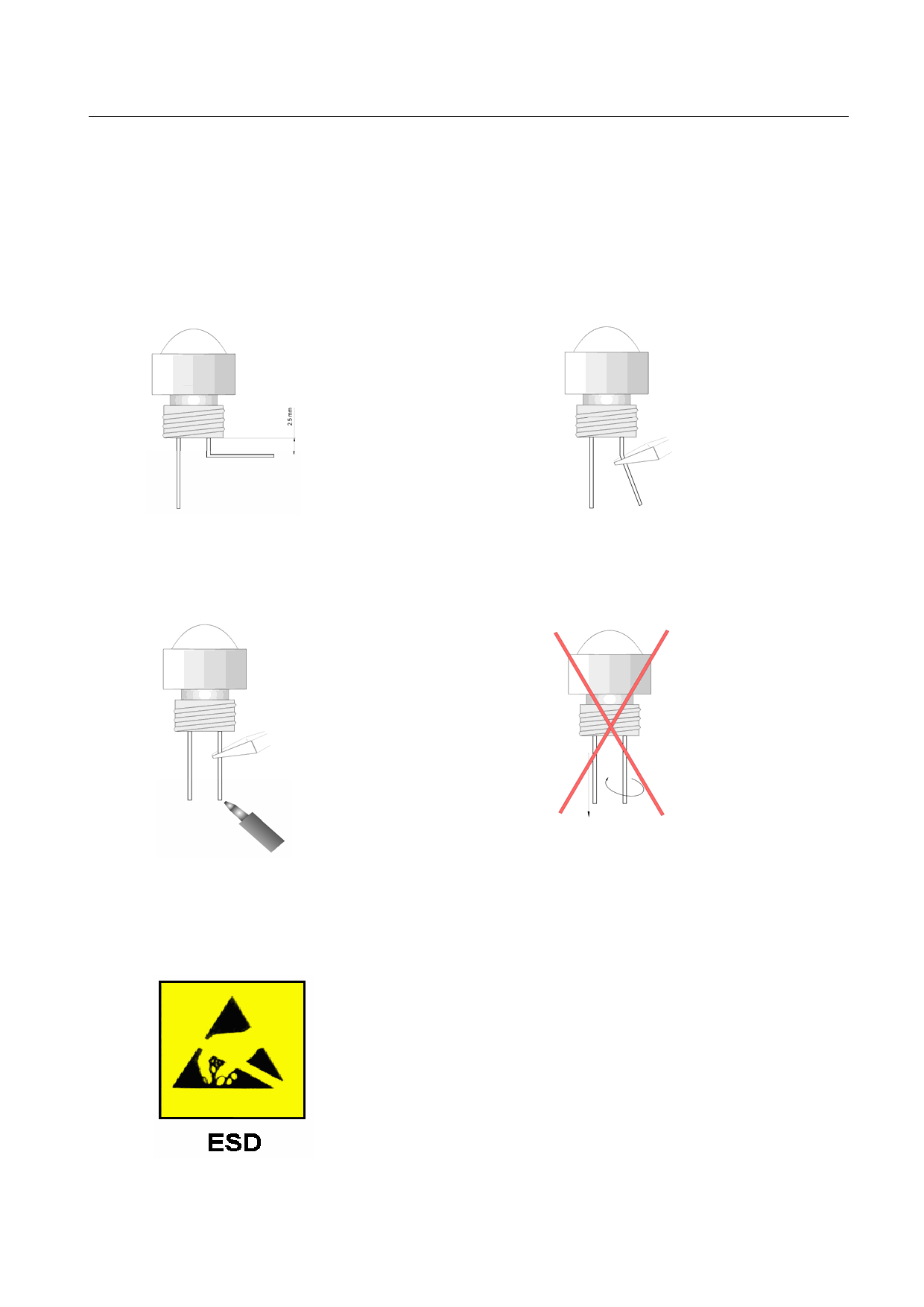

To prevent damage to the LED during soldering and assembly, following precautions have to be

taken into account.

a) The bending point of the lead frame

should be located at least 2.5 mm away

from the body.

b) While bending, the base of the lead

frame has to be fixed with radio pliers or

similar.

c) To ensure an adequate strain relief, the

lead frames have to be firmly fixed during

soldering.

d) Avoid any torsion or tensile loading of

the lead frames, especially when they

have been heated after being soldered.

e) LEDs are static sensitive devices, so

adequate handling precautions have to be

taken, e.g. wearing grounding wrist straps.

We reserve the right to make changes to improve technical design and may do so without further notice.

Parameters can vary in different applications.All operating parameters must be validated for each customer application by the customer.

EPIGAP Optoelektronik GmbH, D-12555 Berlin, Köpenicker Str.325 b, Haus 201

Tel.: +49-30-6576 2543, Fax : +49-30-6576 2545

5 of 5

www.DataSheet.in

5 Page | ||

| Páginas | Total 5 Páginas | |

| PDF Descargar | [ Datasheet ELJ-750-629.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| ELJ-750-629 | Jumbo-LED | EPIGAP |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |