|

|

PDF TB6581H Data sheet ( Hoja de datos )

| Número de pieza | TB6581H | |

| Descripción | 3-Phase Full-Wave Sine-Wave PWM Brushless Motor Controller | |

| Fabricantes | Toshiba Semiconductor | |

| Logotipo | ||

Hay una vista previa y un enlace de descarga de TB6581H (archivo pdf) en la parte inferior de esta página. Total 14 Páginas | ||

|

No Preview Available !

www.DataSheet4U.com

TB6581H/HG

TOSHIBA Bi-CMOS Power Integrated Circuit Multi-Chip Package (MCP)

TB6581H/HG

3-Phase Full-Wave Sine-Wave PWM Brushless Motor Controller

The TB6581H/HG is a high-voltage PWM BLDC motor driver.

The product integrates the TB6551F/FG sine-wave controller and

the TPD4103AK high-voltage driver in a single package (“2-in-1”).

It is designed to change the speed of a BLDC directly motor by

using a speed control signal (analog) from a microcontroller.

Features

• A sine wave PWM drive controller and a high-voltage driver

integrated in a single package.

• IGBTs arranged in three half-bridge units

• Triangle wave generator (carrier frequency = fosc/254 (Hz))

Weight:

• Dead-time insertion (1.9 µs)

HZIP25-P-1.00K: 7.7 g (typ.)

• High-side bootstrap supply

• Bootstrap diode

• Overcurrent protection, thermal shutdown, and undervoltage lockout

• On-chip regulator (Vreg = 7 V (typ.), 30 mA (max),

Vrefout = 5 V (typ.), 30 mA (max))

• Operating power supply voltage range: VCC = 13.5~16.5 V

• Motor power supply operating voltage range: VB = 50~400 V

TB6581HG:

TB6581HG is a Pb-free product.

The following conditions apply to solderability:

*Solderability

1. Use of Sn-63Pb solder bath

*solder bath temperature = 230˚C

*dipping time = 5 seconds

*number of times = once

*use of R-type flux

2. Use of Sn-3.0Ag-0.5Cu solder bath

*solder bath temperature = 245˚C

*dipping time = 5 seconds

*the number of times = once

*use of R-type flux

1 2004-03-01

1 page

www.DataSheet4U.com

TB6581H/HG

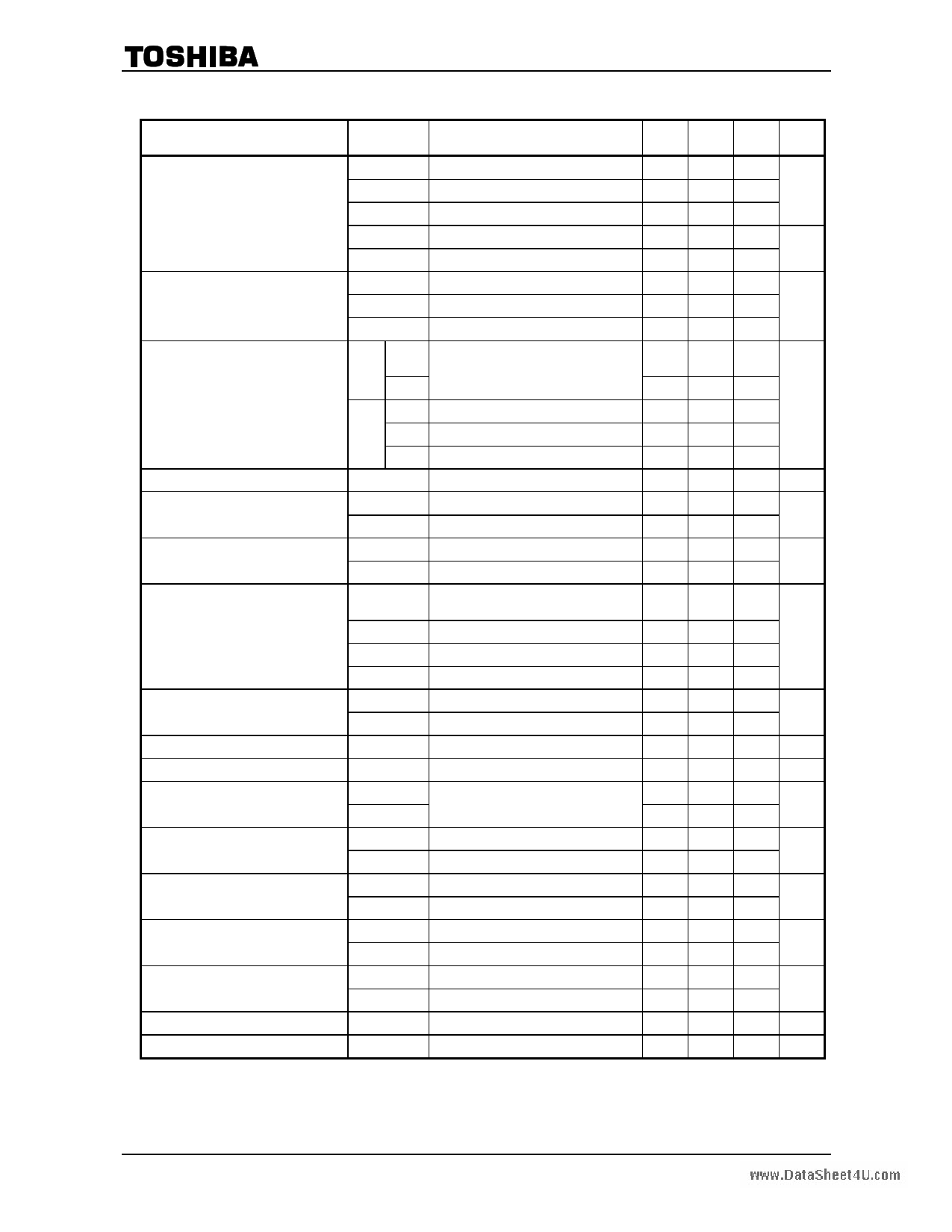

Electrical Characteristics (Ta = 25°C)

Characteristics

Symbol

Test Condition

Min Typ. Max Unit

Current dissipation

Input current

Input voltage

IB

ICC15

ICC7

IBS (ON)

IBS (OFF)

Iin (LA)

Iin (Ve)

Iin (Hall)

VB = 400 V

Vreg = OPEN, VCC = 15 V

Vrefout = OPEN, VCC = 7 V

VBS = 15 V, high-side ON

VBS = 15 V, high-side OFF

Vin = 5 V, LA

Vin = 5 V, Ve

Vin = 0 V, HU, HV, HW

Vin

(Hall)

HIGH

HU, HV, HW

LOW

HIGH PWM Duty 100%

Vin

(Ve)

Middle Refresh → Start motor operation

LOW Turned-off → Refresh

⎯ 0.1 0.5

⎯ 1.1

3

⎯3

6

⎯ 260 410

⎯ 230 370

⎯ 25 50

⎯ 35 70

−50 −25 ⎯

Vrefout

−1

⎯

Vrefout

⎯ ⎯ 0.8

5.1 5.4 5.7

1.8 2.1 2.4

0.7 1.0 1.3

Input hysteresis voltage

Input delay time

Output saturation voltage

VH

VDT

VDC

VCEsatH

VCEsatL

VFG (H)

HU, HV, HW

(Note 6) ⎯

0.3

HU, HV, HW

Xin = 4.19 MHz

⎯ 4.0

Idc

Xin = 4.19 MHz

⎯ 4.0

VCC = 15 V, IC = 0.5 A

⎯ 2.4

VCC = 15 V, IC = 0.5 A

⎯ 2.4

IOUT = 1 mA

FG

Vrefout Vrefout

− 1.0 − 0.2

⎯

⎯

⎯

3

3

⎯

Output voltage

FRD forward voltage

BSD forward voltage

Current detection

Thermal shutdown protection

VFG (L) IOUT = −1 mA

FG

⎯ 0.2 1.0

Vrefout

IOUT = 30 mA

Vrefout

4.5 5.0 5.5

Vreg

IOUT = 30 mA

6.5 7 7.5

VFH IF = 0.5 A, high-side

⎯ 1.3 2.0

VFL IF = 0.5 A, low-side

⎯ 1.3 2.0

VF (BSD) IF = 500 µA

⎯ 0.9 1.2

Vdc Idc

0.47 0.5 0.53

TSD

TSDhys

150 165 200

(Note 7)

⎯ 20 ⎯

VCC15 undervoltage protection for

driver

VBS undervoltage protection for driver

VCC15 (H)

VCC15 (L)

VBS (H)

VBS (L)

Undervoltage positive-going threshold

Undervoltage negative-going threshold

Undervoltage positive-going threshold

Undervoltage negative-going threshold

10.5

10

8.5

8

11.5

11

9.5

9

12.5

12

10.5

10

VCC7 undervoltage protection for

controller

Output turn-on/-off delay time

Dead time

FRD reverse recovery time

VCC7 (H) Undervoltage positive-going threshold 4.2 4.5 4.8

VCC7 (L) Undervoltage negative-going threshold 3.7 4.0 4.3

ton

VBB = 280 V, VCC = 15 V, IC = 0.5 A

⎯ 1.5

3

toff VBB = 280 V, VCC = 15 V, IC = 0.5 A ⎯ 1.2 3

tdead

Xin = 4.19 MHz

1.5 1.8 ⎯

trr

VBB = 280 V, VCC = 15 V, IC = 0.5 A

⎯ 200 ⎯

mA

µA

µA

V

V

µs

V

V

V

V

V

°C

V

V

V

µs

µs

ns

Note 6 and Note 7: Toshiba does not implement testing before shipping.

5 2004-03-01

5 Page

www.DataSheet4U.com

TB6581H/HG

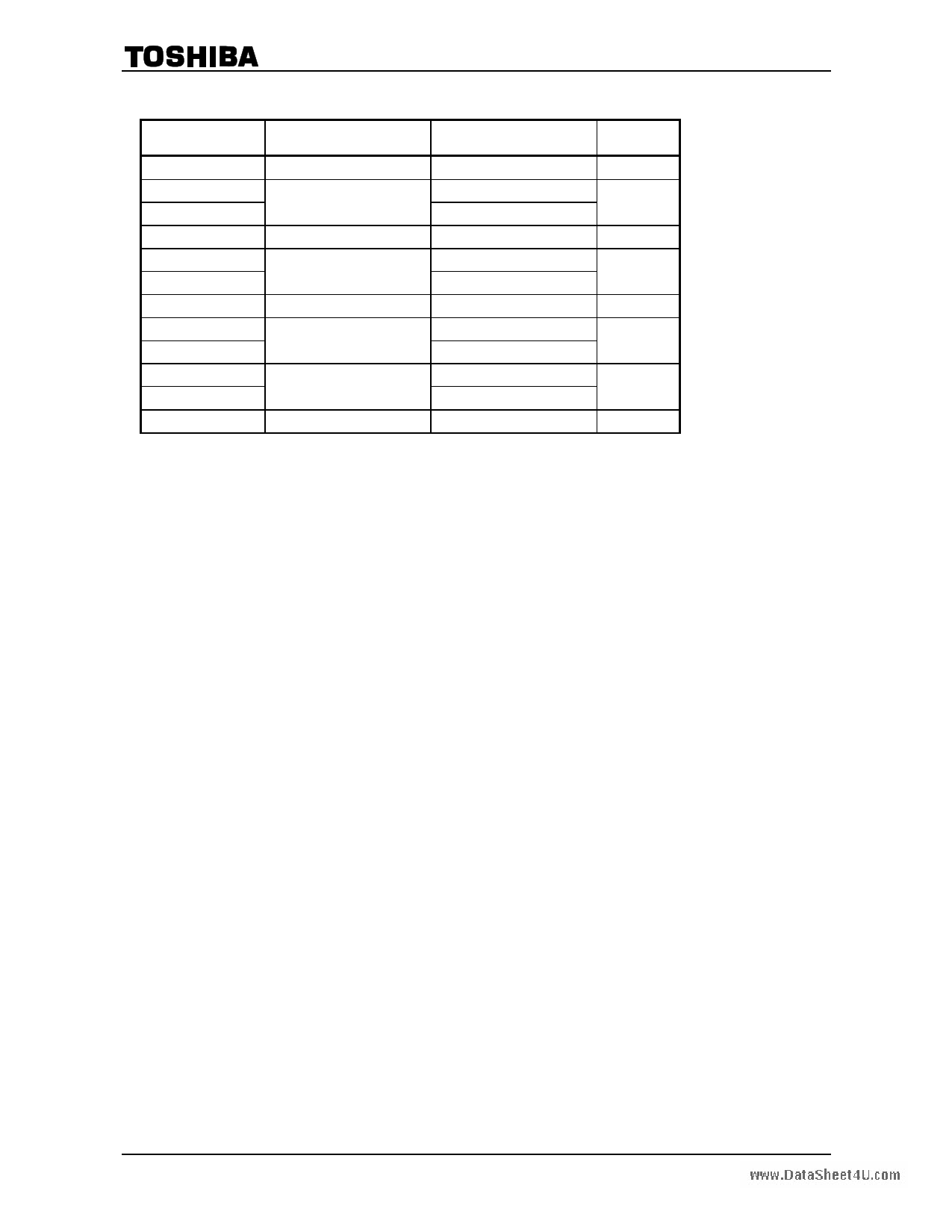

External Parts

Symbol

Purpose

Recommended value

Note

X1

C1, C2, C3

R1, R2, R3

C4

C5

R4

R5

C6

C7

C8

C9

C10, C11, C12

Internal clock generation

Noise absorber

Vrefout oscillation protection

Noise absorber

Overcurrent detection

VREG power supply stability

VCC15 power supply stability

Bootstrap capacitor

4.19 MHz

10 V/1000 pF

10 kΩ

10 V/0.1 µF~1.0 µF

10 V/1000pF

5.1 kΩ

0.62 Ω ± 1% (1 W)

16 V/1.0 µF~10 µF

10 V/1000 pF

25 V/0.1 µF

25 V/10 µF

25 V/2.2 µF

(Note 1)

(Note 2)

(Note 3)

(Note 2)

(Note 4)

(Note 3)

(Note 3)

(Note 5)

Note 1: For carrier frequency and dead time, connect a 4.19 MHz ceramic resonator.

Note 2: These parts are used as a low-pass filter for noise absorption. Test to confirm noise filtering, then set the

filter time-constant.

Note 3: This part is used as a capacitor for power supply stability. Adjust the part to the application environment as

required. When mounting, place it as close as possible to the base of the leads of this product to improve

the noise elimination.

Note 4: This part is used to set the value for overcurrent detection. Iout (max) = Vdc ÷ R5 (Vdc = 0.5 V (typ.))

Note 5: The required bootstrap capacitance value varies according to the motor drive conditions. The voltage stress

for the capacitor is the value of VCC15.

Other Precautions

A short circuit between the outputs, or between output and supply or ground may damage the device. Peripheral

parts may also be damaged by overvoltage and overcurrent. Design the output lines, VCC and GND lines so that

short circuits do not occur.

Also be careful not to insert the IC in the wrong direction because this could destroy the IC.

In turning on the power, first supply Vcc15 and confirm its stability; then apply Vcc7 and the driving input signal.

Vcc15 and VB may be turned on in either order. In turning off the power, take care not to cut off the VB line by

relay while the motor is spinning. Doing so may cause the IC to break down by cutting the current-producing route

for VB.

The TB6581H/HG is sensitive to electrostatic discharge. Handle with care.

The product should be mounted by the solder-flow method. The preheating time is from 60 to 120 seconds at

150˚C. The maximum heat is 260˚C, to be applied within 10 seconds and as far as the lead stopper.

11 03/12/25

11 Page | ||

| Páginas | Total 14 Páginas | |

| PDF Descargar | [ Datasheet TB6581H.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| TB6581H | 3-Phase Full-Wave Sine-Wave PWM Brushless Motor Controller | Toshiba Semiconductor |

| TB6581HG | 3-Phase Full-Wave Sine-Wave PWM Brushless Motor Controller | Toshiba Semiconductor |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |