|

|

PDF MAX1460 Data sheet ( Hoja de datos )

| Número de pieza | MAX1460 | |

| Descripción | Low-Power / 16-Bit Smart ADC | |

| Fabricantes | Maxim Integrated | |

| Logotipo |  |

|

Hay una vista previa y un enlace de descarga de MAX1460 (archivo pdf) en la parte inferior de esta página. Total 18 Páginas | ||

|

No Preview Available !

MAX1460

EVALUATION KIT AVAILABLE

Low-Power, 16-Bit Smart ADC

General Description

The MAX1460 implements a revolutionary concept in signal

conditioning, where the output of its 16-bit analog- to-digital

converter (ADC) is digitally corrected over the specified

temperature range. This feature can be readily exploited

by industrial and medical market segments, in applications

such as sensors and smart batteries. Digital correction is

provided by an internal digital signal processor (DSP) and

on-chip 128-bit EEPROM containing user-programmed

calibration coefficients. The conditioned output is available

as a 12-bit digital word and as a ratiometric (proportional

to the supply voltage) analog voltage using an on-board

12-bit digital-to-analog converter (DAC). The uncommitted

op amp can be used to filter the analog output, or imple-

ment a 2-wire, 4–20mA transmitter.

The analog front end includes a 2-bit programmablegain

amplifier (PGA) and a 3-bit coarse-offset (CO) DAC,

which condition the sensor’s output. This coarsely cor-

rected signal is digitized by a 16-bit ADC. The DSP uses

the digitized sensor signal, the temperature sensor, and

correction coefficients stored in the internal EEPROM to

produce the conditioned output.

Multiple or batch manufacturing of sensors is supported with a

completely digital test interface. Built-in testability features on

the MAX1460 result in the integration of three traditional sen-

sor-manufacturing operations into one automated process:

●● Pretest: Data acquisition of sensor performance under

the control of a host test computer.

●● Calibration and Compensation: Computation and stor-

age of calibration and compensation coefficients

determined from transducer pretest data.

●● Final Test Operation: Verification of transducer cali-

bration and compensation, without removal from the

pretest socket.

The MAX1460 evaluation kit (EV kit) allows fast evaluation

and prototyping, using a piezoresistive transducer (PRT) and

a Windows®-based PC. The user-friendly EV kit simplifies

small-volume prototyping; it is not necessary to fully under-

stand the test-system interface, the calibration algorithm, or

many other details to evaluate the MAX1460 with a particular

sensor. Simply plug the PRT into the EV kit, plug the EV kit

into a PC parallel port, connect the sensor to an excitation

source (such as a pressure controller), and run the MAX1460

EV kit software. An oven is required for thermal compensation

Functional Diagram appears at end of data sheet.

Pin Configuration appears at end of data sheet.

Windows is a registered trademark of Microsoft Corp.

Features

●● Low-Noise, 400μA Single-Chip Sensor Signal

Conditioning

●● High-Precision Front End Resolves Less than 1μV of

Differential Input Signal

●● On-Chip DSP and EEPROM Provide Digital

Correction of Sensor Errors

●● 16-Bit Signal Path Compensates Sensor Offset and

Sensitivity and Associated Temperature Coefficients

●● 12-Bit Parallel Digital Output

●● Analog Output

●● Compensates a Wide Range of Sensor Sensitivity

and Offset

●● Single-Shot Automated Compensation

Algorithm—No Iteration Required

●● Built-In Temperature Sensor

●● Three-State, 5-Wire Serial Interface Supports

High-Volume Manufacturing

Applications

●● Hand-Held Instruments

●● Piezoresistive Pressure and Acceleration

Transducers and Transmitters

●● Industrial Pressure Sensors and 4–20mA

Transmitters

●● Smart Battery Charge Systems

●● Weigh Scales and Strain-Gauge Measurement

●● Flow Meters

●● Dive Computers and Liquid-Level Sensing

●● Hydraulic Systems

Ordering Information

PART

TEMP RANGE

PIN-PACKAGE

MAX1460CCM

0°C to +70°C

48 TQFP

Customization

Maxim can customize the MAX1460 for unique require-

ments. With a dedicated cell library of more than 90 sen-

sor- specific functional blocks, Maxim can quickly provide

customized MAX1460 solutions, including customized

microcode for unusual sensor characteristics. Contact

Maxim for further information.

19-4784; Rev 1; 5/14

1 page

MAX1460

Low-Power, 16-Bit Smart ADC

Pin Description (continued)

PIN NAME

FUNCTION

27 D3 Parallel Digital Output - bit 3

28 D4 Parallel Digital Output - bit 4

28 D5 Parallel Digital Output - bit 5

30

OUT

Output DAC. The bitstream on OUT, when externally filtered, creates a ratiometric analog output

voltage. OUT is proportional to the 12-bit parallel digital output.

33 AMPOUT General-Purpose Operational Amplifier Output

34 AMP+ Noninverting Input of General-Purpose Operational Amplifier

35 AMP- Inverting Input of General-Purpose Operational Amplifier

39

XOUT

Internal Oscillator Output. Connect a 2MHz ceramic resonator (Murata CST200) or crystal from XOUT

to XIN.

40

XIN

Internal Oscillator Input. When TEST is high, this pin must be driven by the test system with a 2MHz,

50% duty cycle clock signal. The resonator does not need to be disconnected in test mode.

46 INP Positive Sensor Input. Input impedance is typically > 1MΩ. Rail-to-Rail® input range.

47

TEST

Test/Program Mode Enable Input. When high, enables the MAX1460 programming/testing operations.

Internally pulled to VSS with a 1MΩ (typical) resistor.

48 INM Negative Sensor Input. Input impedance is typically > 1MΩ. Rail-to-rail input range.

Rail-to-Rail is a registered trademark of Nippon Motorola, Ltd.

www.maximintegrated.com

Maxim Integrated │ 5

5 Page

MAX1460

Low-Power, 16-Bit Smart ADC

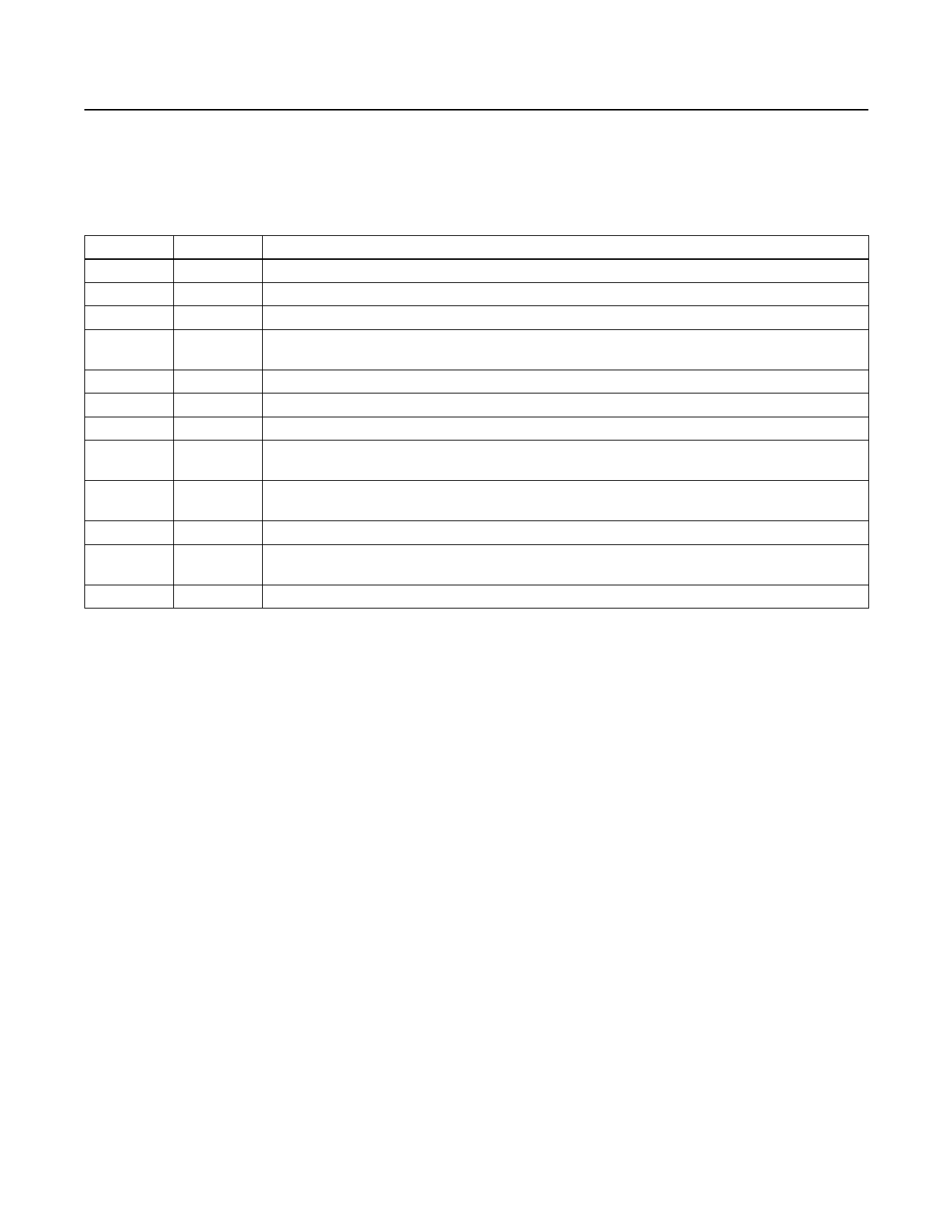

Table 6. Configuration Register Bitmap

EEPROM

ADDRESS

(HEX)

01

02

03

04

05

06

07

08

09

0A

0B

0C

0D

0E

0F

10

BIT

POSITION

DESCRIPTION

0 (LSB)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15 (MSB)

CO-0 (LSB)

CO-1 (MSB)

CO-S (Sign)

PGA-1 (MSB)

PGA-0 (LSB)

Maxim Reserved

Maxim Reserved

Op Amp Power-Down

Maxim Reserved

TSO-0 (LSB)

TSO-1

TSO-2 (MSB)

Maxim Reserved

Maxim Reserved

Maxim Reserved

Repeat Mode

Writing to the Internal EEPROM

The test system writes to the EEPROM with commands

4 hex (Block-Erase the entire EEPROM), 2 hex (Write

“1” to a single EEPROM bit) and 0 hex (NOOP). During

normal operation (when the TEST pin is low) or when

the test system issues instructions A hex or E hex (Start

conversion from EEPROM values), the DSP reads the

Calibration Coefficients from the EEPROM.

In the normal production flow, determine the calibra-

tion coefficients using direct register access. Then load

the calibration coefficients into the EEPROM with tester

instruction 2 hex. Instruction 4 hex block-erases the

EEPROM and is necessary only for a rework or reclaim

operation. For each part, the Maxim reserved bits in the

Configuration Register should be read before instruction

4 hex is issued, and restored afterwards. The MAX1460

is shipped with its internal EEPROM uninitialized, except

for the reserved bits.

The internal 128-bit EEPROM is arranged as eight 16- bit

words. These eight words are the configuration register

and the seven calibration-coefficient values (Table 7).

The MAX1460 EEPROM is bit addressable. The final cali-

bration coefficients must be mapped into the EEPROM

locations that are to be set. There is no bitclear instruc-

tion. Any EEPROM write operation is necessarily long

because the internal charge pump must create and main-

tain voltages above 20V long enough to cause a reliably

permanent change in the memory.

Writing an EEPROM bit requires 6ms, so writing the

EEPROM typically requires less than 400ms. Do not

decrease the EEPROM write times.

To write an EEPROM bit, the test system must be compli-

ant with the Command Timing Diagram shown in Figure

3, performing the following operations:

1) Issue command 0 hex, including the EEPROM address

field of the bit to be written.

2) Issue command 2 hex, with the address field used in

step 1. Continuously repeat this command 375 times

(6ms).

3) Issue command 0 hex, including the EEPROM address

field used in steps 1 and 2.

The procedure for using command 4 hex (Block-Erase

the EEPROM) is similar. Record the Maxim Reserved bits

in the configuration register prior to using this command,

and restore them afterwards. The number of Block-Erase

operations should not exceed 100.

1) Issue command 0 hex.

2) Issue command 4 hex. Continuously repeat this com-

mand 375 times (6ms).

3) Issue command 0 hex.

Test System Interface:

Observing the DSP Operation

Test system commands 8 hex and A hex initiate a conver-

sion while allowing the test system to observe the opera-

tion of the DSP. To calibrate a unit, the test system must

know the digitized temperature and sensor signals, stored

in DSP registers 8 and 9, and the calibrated and compen-

sated output stored in DSP register 10. The test system

should also verify the EEPROM contents, registers 0–7.

All these signals pass through DSP register S during the

execution of the instruction ROM microcode. The SDO pin

outputs the S register values, and the SDIO pin tells the

tester which signal is currently on S.

www.maximintegrated.com

Maxim Integrated │ 11

11 Page | ||

| Páginas | Total 18 Páginas | |

| PDF Descargar | [ Datasheet MAX1460.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| MAX146 | +2.7Low-Power / 8-Channel / Serial 12-Bit ADCs | Maxim Integrated |

| MAX1460 | Low-Power / 16-Bit Smart ADC | Maxim Integrated |

| MAX1460CCM | Low-Power / 16-Bit Smart ADC | Maxim Integrated |

| MAX14611 | Quad Bidirectional Low-Voltage Logic-Level Translator | Maxim Integrated |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |