|

|

PDF RF1K49224 Data sheet ( Hoja de datos )

| Número de pieza | RF1K49224 | |

| Descripción | 3.5A/2.5A/ 30V/ 0.060/0.150 Ohms/ Complementary LittleFET Power MOSFET | |

| Fabricantes | Intersil Corporation | |

| Logotipo |  |

|

Hay una vista previa y un enlace de descarga de RF1K49224 (archivo pdf) en la parte inferior de esta página. Total 14 Páginas | ||

|

No Preview Available !

Data Sheet

RF1K49224

August 1999 File Number 4330.1

3.5A/2.5A, 30V, 0.060/0.150 Ohms,

Complementary LittleFET™ Power

MOSFET

The RF1K49224 complementary power MOSFET is

manufactured using an advanced MegaFET process. This

process, which uses feature sizes approaching those of LSI

integrated circuits, gives optimum utilization of silicon,

resulting in outstanding performance. It is designed for use

in applications such as switching regulators, switching

converters, motor drivers, relay drivers, and low voltage bus

switches. This device can be operated directly from

intergrated circuits.

Formerly developmental type TA49224.

Ordering Information

PART NUMBER

PACKAGE

BRAND

RF1K49224

MS-012AA

RF1K49224

NOTE: When ordering, use the entire part number. For ordering in

tape and reel, add the suffix 96 to the part number, i.e. RF1K4922496.

Features

• 3.5A, 30V (N-Channel)

2.5A, 30V (P-Channel)

• rDS(ON) = 0.060Ω (N-Channel)

rDS(ON) = 0.150Ω (P-Channel)

• Temperature Compensating PSPICE® Model

• Thermal Impedance PSPICE Model

• Peak Current vs Pulse Width Curve

• UIS Rating Curve

• Related Literature

- TB334 “Guidelines for Soldering Surface Mount

Components to PC Boards”

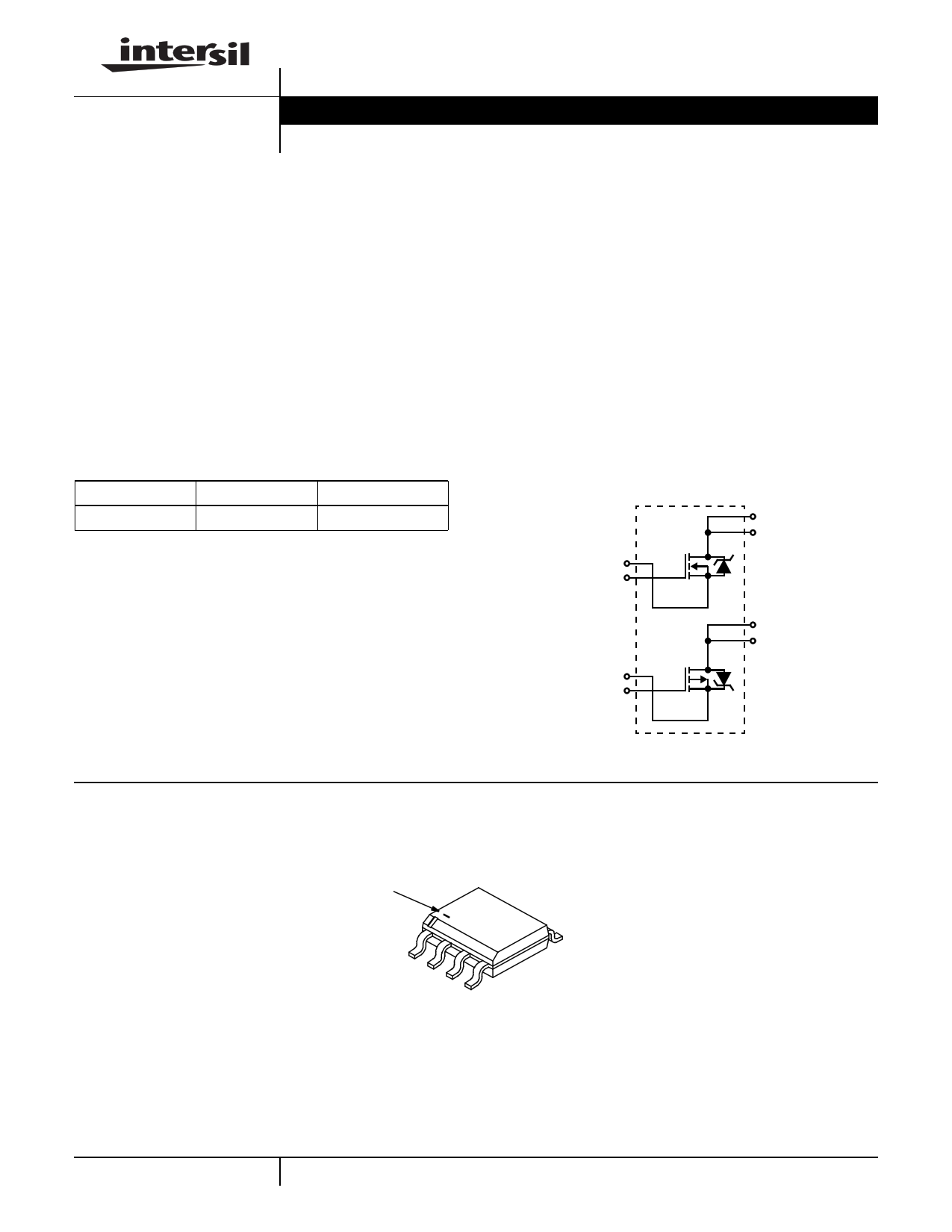

Symbol

S1(1)

G1(2)

D1(8)

D1(7)

S2(3)

G2(4)

D2(6)

D2(5)

Packaging

JEDEC MS-012AA

BRANDING DASH

1

2

3

4

5

9-16

CAUTION: These devices are sensitive to electrostatic discharge; follow proper ESD Handling Procedures.

LittleFET™ is a trademark of Intersil Corporation. PSPICE® is a registered trademark of MicroSim Corporation.

http://www.intersil.com or 407-727-9207 | Copyright © Intersil Corporation 1999

1 page

RF1K49224

Typical Performance Curves (N-Channel) (Continued)

25

PULSE DURATION = 80µs

DUTY CYCLE = 0.5% MAX

20

25oC

-55oC

15

VDD = 15V

150oC

250 PULSE DURATION = 80µs

DUTY CYCLE = 0.5% MAX

200

ID = 7.0A

ID = 3.5A

VDD = 15V

ID = 1.75A

150

10

5

0

0 1.5 3.0 4.5 6.0

VGS, GATE TO SOURCE VOLTAGE (V)

FIGURE 8. TRANSFER CHARACTERISTICS

7.5

100

ID = 0.5A

50

0

3 4 5 6 7 8 9 10

VGS, GATE TO SOURCE VOLTAGE (V)

FIGURE 9. DRAIN TO SOURCE ON RESISTANCE vs GATE

VOLTAGE AND DRAIN CURRENT

2.0

PULSE DURATION = 80µs

DUTY CYCLE = 0.5% MAX

VGS = 10V, ID = 3.5A

1.5

2.0

VGS = VDS, ID = 250µA

1.5

1.0 1.0

0.5 0.5

0

-80 -40

0 40 80 120 160

TJ, JUNCTION TEMPERATURE (oC)

FIGURE 10. NORMALIZED DRAIN TO SOURCE ON

RESISTANCE vs JUNCTION TEMPERATURE

2.0

ID = 250µA

1.5

1.0

0.5

0

-80 -40 0 40 80 120 160

TJ, JUNCTION TEMPERATURE (oC)

FIGURE 12. NORMALIZED DRAIN TO SOURCE BREAKDOWN

VOLTAGE vs JUNCTION TEMPERATURE

9-20

0

-80 -40

0 40 80 120 160

TJ, JUNCTION TEMPERATURE (oC)

FIGURE 11. NORMALIZED GATE THRESHOLD VOLTAGE vs

JUNCTION TEMPERATURE

100 0

750

500

CISS

COSS

VGS = 0V, f = 1MHz

CISS = CGS + CGD

CRSS = CGD

COSS = CDS + CGD

250

CRSS

0

0 5 10 15 20 25

VDS, DRAIN TO SOURCE VOLTAGE (V)

FIGURE 13. CAPACITANCE vs DRAIN TO SOURCE VOLTAGE

5 Page

RF1K49224

Soldering Precautions

The soldering process creates a considerable thermal stress

on any semiconductor component. The melting temperature

of solder is higher than the maximum rated temperature of

the device. The amount of time the device is heated to a high

temperature should be minimized to assure device reliability.

Therefore, the following precautions should always be

observed in order to minimize the thermal stress to which

the devices are subjected.

1. Always preheat the device.

2. The delta temperature between the preheat and soldering

should always be less than 100oC. Failure to preheat the

device can result in excessive thermal stress which can

damage the device.

3. The maximum temperature gradient should be less than 5oC

per second when changing from preheating to soldering.

4. The peak temperature in the soldering process should be

at least 30oC higher than the melting point of the solder

chosen.

5. The maximum soldering temperature and time must not

exceed 260oC for 10 seconds on the leads and case of

the device.

6. After soldering is complete, the device should be allowed

to cool naturally for at least three minutes, as forced cool-

ing will increase the temperature gradient and may result

in latent failure due to mechanical stress.

7. During cooling, mechanical stress or shock should be

avoided.

9-26

11 Page | ||

| Páginas | Total 14 Páginas | |

| PDF Descargar | [ Datasheet RF1K49224.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| RF1K49221 | 2.5A/ 60V/ 0.130 Ohm/ ESD Rated/ Dual N-Channel LittleFET Power MOSFET | Intersil Corporation |

| RF1K49223 | 2.5A/ 30V/ 0.150 Ohm/ Dual P-Channel LittleFET Power MOSFET | Fairchild Semiconductor |

| RF1K49223 | 2.5A/ 30V/ 0.150 Ohm/ Dual P-Channel LittleFET Power MOSFET | Intersil Corporation |

| RF1K49224 | 3.5A/2.5A/ 30V/ 0.060/0.150 Ohms/ Complementary LittleFET Power MOSFET | Intersil Corporation |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |