|

|

PDF FPC1011F Data sheet ( Hoja de datos )

| Número de pieza | FPC1011F | |

| Descripción | Area Sensor Package | |

| Fabricantes | FINGERPRINTS | |

| Logotipo |  |

|

Hay una vista previa y un enlace de descarga de FPC1011F (archivo pdf) en la parte inferior de esta página. Total 30 Páginas | ||

|

No Preview Available !

FPC1011F Area Sensor Package

Product Specification

Features

• Fingerprint area sensor

• NEW hard and scratch resistant protective surface coating

• Superior image quality

• 3D image with 256 true gray scale values

• Ergonomic frame for optimized finger guidance

• High speed SPI interface or Parallel interface

• Flex connector or BGA

• 3.3 and 2.5 volt operation

• >15kV ESD protection

• >1 million wear cycles

Application examples

• Computer peripheral

• Physical access control

• Time and attendance

• Wireless devices

• Security application

• Medical equipment & storage

General description

FPC1011F is a new compact CMOS fingerprint sensor with several significant advantages. FPC1011F

deliveries superior image quality, with 256 gray scale values in every single pixel. The reflective

measurement method sends an electrical signal via the frame directly into the finger. This technique

enables the use of an unbeatably hard and thick protective surface coating. The sensor with its 3D pixel

sensing technology can read virtually any finger; dry or wet.

Thanks to the new extremely hard and durable surface coating, FPC1011F is protected against ESD well

above 15 kV, as well as scratches, impact and everyday wear-and-tear. FPC1011F is delivered with a

designed micro-ergonomic guidance frame, simplifying proper fingerprint guidance and hence improving

algorithm performance.

FPC1011F is available in two configurations; either a versatile flex connector version, FPC1011F1, with a

serial SPI interface or a standard BGA component, FPC1011F2, with both serial and parallel interface. In

higher volumes, the micro-ergonomic frame can be made available in different colors and textures.

Quick reference data

PARAMETER

Dimension

Interface

Supply voltage

Supply current

Supply current sleep mode

Clock frequency

Read out speed

Active sensing area

Size sensing array

Pixel resolution

ESD protection

Wear-and-tear

DESCRIPTION

Sensor body (W x L x T)

Serial SPI or Parallel

VDC

Typical at 3.3V, 4MHz and RT

Power down

Serial SPI or Parallel

Serial SPI or Parallel

Pixel matrix

Pixel matrix (363 dpi)

256 gray scale values

IEC61000-4-2, level 4, air discharge

No of wear cycles at 6N

VALUE

20.4 x 33.4 x 2.3

8 / 32

2.5 - 3.3

7

10

32

4

10.64 x 14.00

152 x 200

8

> 15

> 1 million

UNIT

mm

pin

V

mA

μA

MHz

Mpixel/s

mm

pixel

bit

kV

cycle

This specification is subject to changes without prior notice

710‐FPC1011F_D_Product‐specification.doc

www.fingerprints.com

1

1 page

FPC1011F Area Sensor Package

Product Specification

2 Electrical characteristics

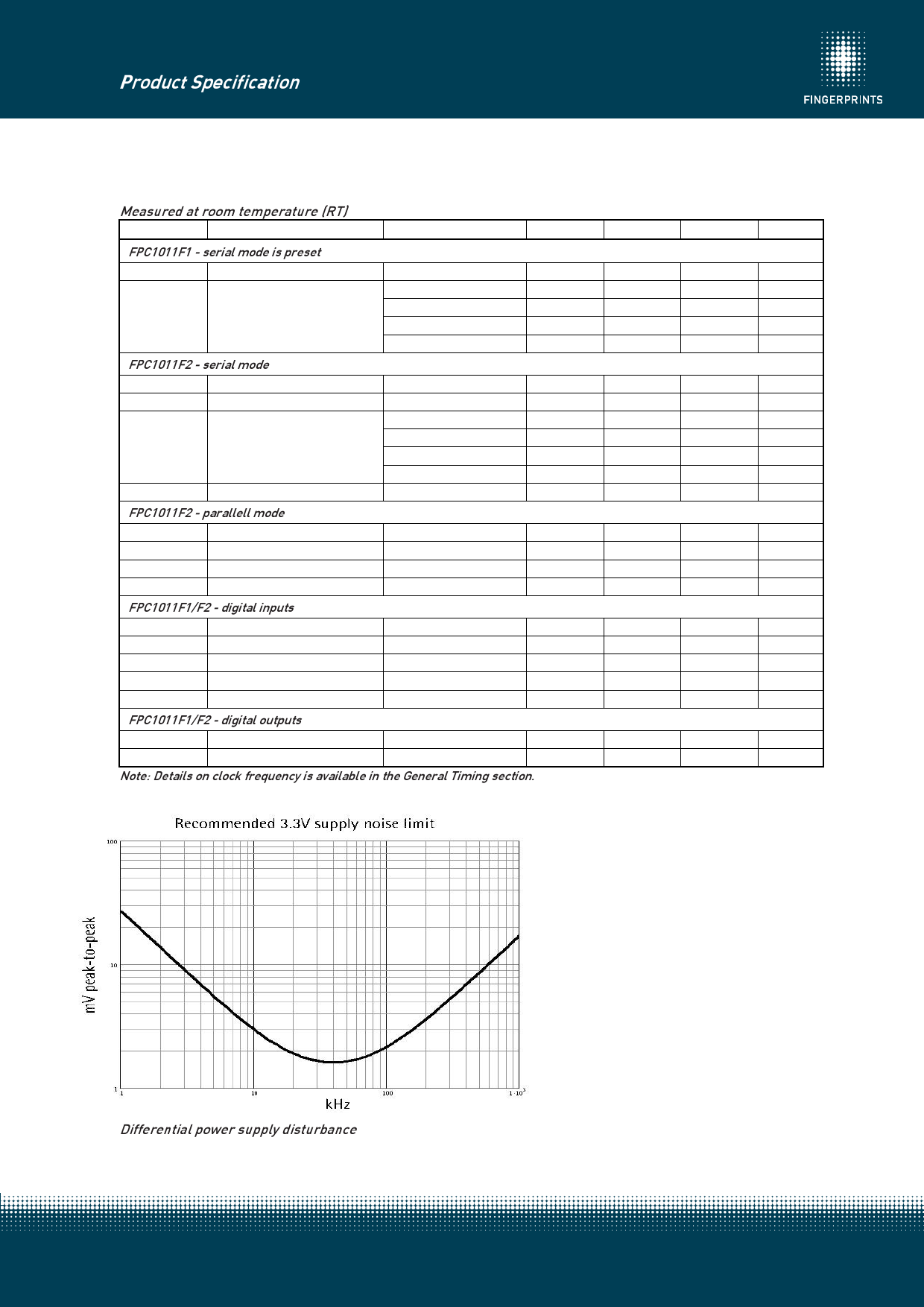

Measured at room temperature (RT)

SYMBOL PARAMETER

CONDITION

FPC1011F1 - serial mode is preset

VDD Voltage supply (total)

IDD Current supply, total

FPC1011F2 - serial mode

VDD = 2.5V@4MHz

VDD = 2.5V@32MHz

VDD = 3.3V@4MHz

VDD = 3.3V@32MHz

VDD

AVDD

IDD

Voltage supply (digital)

Analog voltage supply

Current supply, total

IDDS Current supply, sleep mode

FPC1011F2 - parallell mode

VDD = 2.5V@4MHz

VDD = 2.5V@32MHz

VDD = 3.3V@4MHz

VDD = 3.3V@32MHz

PWRDN high

VDD Voltage supply (digital)

AVDD

Analog voltage supply

IDD Current supply, total

IDDS Current supply, sleep mode

FPC1011F1/F2 - digital inputs

VDD = 3.3V@8MHz

PWRDN high

VIL Logic ’0’ voltage

VIH Logic ’1’ voltage

IIL Logic ’0’ current (VI = GND)

IIH Logic ’1’ current (VI = VDD)

CIND Input capacitance

FPC1011F1/F2 - digital outputs

VOL Logic ’0’ output voltage

VOH Logic ’1’ output voltage

Note: Details on clock frequency is available in the General Timing section.

MIN

2.35

-

-

-

-

2.35

2.35

-

-

-

-

-

2.35

2.35

-

-

N/A

0.8VDD

-

-

-

-

0.85VDD

TYP

2.5/3.3

7

9

7

12

2.5/3.3

2.5/3.3

7

9

7

12

10

2.5/3.3

2.5/3.3

TBD

10

N/A

N/A

-

-

6

0.2

0.90VDD

MAX

3.45

14

-

14

-

3.45

3.45

-

-

-

-

-

3.45

3.45

-

-

0.2VDD

N/A

±10

±10

-

0.4

-

UNIT

V

mA

mA

mA

mA

V

V

mA

mA

mA

mA

uA

V

V

mA

uA

V

V

uA

uA

pF

V

V

Differential power supply disturbance

The graph shows the supply disturbance

level (sinus rms), which will give less than

one gray level rms disturbance in the

fingerprint image readout. If the supply

voltage is noisy, additional filtering may be

required.

If separate (splitted) power supplies or long

connection leads are used, it is important to

maintain a synchronized power on voltage

curve (equivalent ramp), for both VDD and

AVDD. This care is necessary to avoid

possible latch-up problems.

This specification is subject to change without prior notice

www.fingerprints.com

710‐FPC1011F D Product‐specification.doc

5

5 Page

FPC1011F Area Sensor Package

Product Specification

Read sensor instruction

INSTRUCTION

Mode

rd_sensor

serial

( 11H )

Input parameters 1 dummy byte

Data delay1

Returned bytes

(363±2)tCLK

0

Note1: Data delay is the delay time from when the

instruction is given, until data is available in

the FIFO. The uncertainty, ±2 clock cycles, is

only valid if separate SPI and system clocks

are used (only possible in FPC1011F2 in serial

mode).

Read SPI data instruction

INSTRUCTION rd_spidata

Mode

serial

Input parameters 1 dummy byte

Data delay

0

Returned bytes

n

( 20H )

After the read SPI data instruction is sent,

<rd_spidata>, pixel data will be returned as shown in

Figure 11. Data will continue to be returned as long

as SPI_CS_N and SPI_DI are kept low.

This instruction is used to read the entire sensor or a

part of it. Timing for reading in serial mode is defined

in the section Timing properties.

SPI_DI should be kept low after the <rd_spidata>,

instruction is entered to avoid the subsequent byte

to be interpreted as a new instruction.

The read sensor instruction is only used to start the

sense-sequence, and the instruction itself does not

return any data. The first data from the sensor array

will enter the FIFO after approximately 363 clock-

cycles. After that, a new byte will enter the FIFO every

8th clock-cycle until the area defined by the XSENSE,

YSENSE, XSHIFT and YSHIFT registers has been read.

When the FIFO is filled to a level equal to or greater

than the value set by the FIFO_TH register, the

SPI_STAT register will indicate that data is ready for

fetching.

The reading of data can be stopped at any time

without data-loss by setting SPI_CS_N high, as long

as SPI_CS_N is set high between the last bit of the

current byte being read and the first bit in the next

byte.

If SPI_CS_N is released at any other time (e.g.

during a byte transfer) one or more bytes will be

lost. To continue readout after a stop caused by

setting SPI_CS_N high, the <rd_spidata> instruction

has to be applied again.

If the FIFO is filled up with data, overflow is avoided

by stalling sensing until data is read from the FIFO.

During this stall-period all analog modules are active,

and the ASIC will draw current as during a regular

sense operation.

This specification is subject to change without prior notice

www.fingerprints.com

710‐FPC1011F D Product‐specification.doc

11

11 Page | ||

| Páginas | Total 30 Páginas | |

| PDF Descargar | [ Datasheet FPC1011F.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| FPC1011C | Area Sensor Package | FINGERPRINTS |

| FPC1011F | Area Sensor Package | FINGERPRINTS |

| FPC1011F3 | Area Sensor Package | FINGERPRINTS |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |